Hot Specials

Featured Products

Brands

-

Freight Increase Notification

Date: 26-02-2024 -

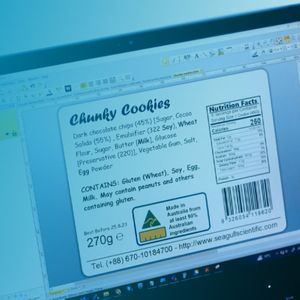

New rules for labelling allergens - Are you ready?

Date: 13-02-2024 -

Powerful Performance for Industrial Applications

Date: 31-10-2023